Controlled atmosphere (CA)

Due to their nature, agricultural commodities often get infested with stored product insects and have to be treated before production or consumption. Besides traditional techniques, non-toxic methods such as low oxygen by in-situ nitrogen are becoming more widespread. An efficient way to treat products such as nuts, corn, rice, cocoa, coffee, spices, dried fruit, seeds, legumes, tobacco, soya wheat and barley pest-free—quickly and efficiently, is by treating them in gastight chambers. This technique is approved by various organic schemes and is often applied in conventional supply chains due to increasing safety and cost considerations.

Clean and safe

Go for non-toxic fumigation

Controlled atmosphere fumigation is applied to control pests in dry commodities and food supplies and is extremely suitable for both preventive and curative treatments. This technique is based on the creation of a low-oxygen regime/content in a specially constructed gastight treatment chamber or container.

Foolproof and bioproof

No resistance

Mortality rate of 100% of all live stages, such as eggs larvae, purpae and adults, without resistance issues associated with for example phosphine

No toxic chemicals

CA uses only in-situ nitrogen from the ambient air

No degassing concerns

CA chambers use ambient air to produce Nitrogen. Removing complex logistics in N2 supplies. After the treatment the normal oxygen/nitrogen balance is immediately recovered, hence there are no degassing concerns

No harm to (organic) products

Permitted in organic production programs such as EU-Organic, USDA-NOP, Japan JAS and Bio Suisse, but also very relevant for (large volume) conventional commodities

No harm for the environment

Treatment facilities are completely safe for workers, consumers, and the environment

Chamber and container installations

Our Controlled atmosphere systems are available in 2 main formats: Tailor made chamber installation at your facility, or set up as container units requiring less time, space and investment.

CA Chamber installation

A Control Union Controlled Atmosphere system enables the establishment of an ideal, low oxygen treatment environment within gastight chambers. Absolute control over the treatment process is eliminating any possibility of insect survival (eggs, larvae, pupae, or adults).

Our Controlled Atmosphere chambers are customizable to accommodate small or large quantities of products requiring treatment, tailored to your production capacity and logistical requirements.

Due to their capacity to accommodate high volumes of goods simultaneously, as well as minimal loss of energy these chambers represent one of the most convenient and effective airtight spaces for commodity treatments. They can be installed in any desired location and are offered in a wide range of capacities.

CA Container installation

Gastight containers provide an ideal solution, especially when a quick setup is needed, or in space-constrained environments. These gastight containers can be conveniently placed either within or outside your facility, offering flexibility in placement.

Similar to our Controlled Atmosphere chambers, the CA Container installation service caters to varying volume requirements. We operate a large stock of these 45ft units, so we can scale up to any desired capacity.

The machine room: design and options

Controlled Atmosphere Chambers require a separate machine room, distinct from the treatment chamber, to perform treatments effectively. These can be set up either in a separate machine room or within a containerized mobile machine room.

Each Controlled Atmosphere setup includes the following essential elements:

• Compressor with integrated dryer

• Nitrogen generator

• Compressed air components

• Temperature humidity and o2 sensors

• Control Union software equipped in English

• Power supplies from (CA) an (MA) switchboxes to all components

• CE standard material incl. Buffertank

One machine can handle multiple Chambers simultaneously

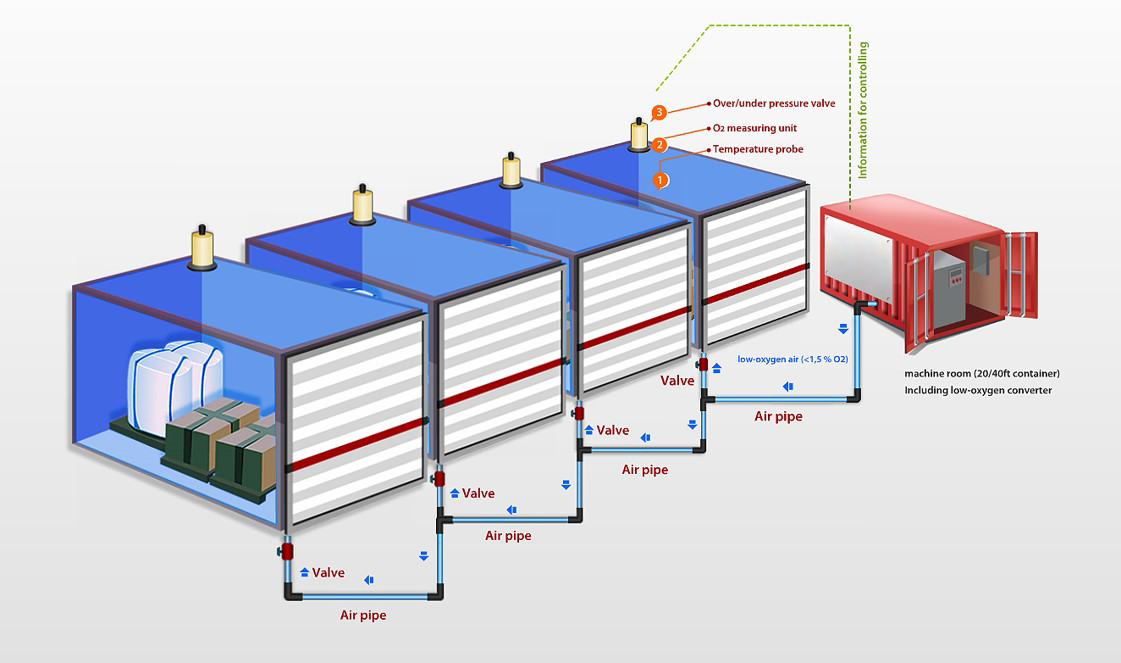

One machine room is able to hande multiple CA chamber at once. Our systems are designed to maintain the quality of perishable goods over extended periods. The system consists of several large, interconnected storage units, each equipped with a temperature probe, an oxygen measuring unit, and an over/under pressure valve to ensure optimal conditions within. These units are connected through a series of air pipes and valves to a central machine room housed in a container. This room contains a low-oxygen converter, crucial for maintaining an atmosphere with less than 1.5% oxygen content.

24/7 monitoring solutions

The treatments are followed and analyzed 24/7 for its major parameters, temperature, oxygen level and relative humidity. Our cloud-based software solution is accessible on all mobile devices, including smartphones and tablets, enabling both on-site and remote monitoring of the heat treatment process. The platform is easy to use by design.. Our solution guarantees results, with built-in functionality to confirm the successful conclusion of treatments, ensuring both energy cost and treatment duration are minimized for efficiency and savings. A globally approved certificate is issued after treatment based on these parameters.

Frequently asked questions (FAQ)

How can we help you?

If you have any questions or if you wish to have a proposal for our services? Do not hesitate to contact us.